Tool Design

Enhance your production efficiency with our precision-engineered mould design services. We specialize in crafting high-performance, durable moulds tailored to your specific manufacturing requirements.

- Custom Core & Cavity Design – Engineered for precision and durability

- Advanced Slider & Insert Integration – Enables complex geometries with ease

- Optimized Cooling & Ejection Systems – Minimizes cycle time and maximizes efficiency

- CAD & Simulation Technology – Ensures flawless mould performance from the outset

From concept to completion, our mould designs are built to boost productivity and deliver long-term reliability.

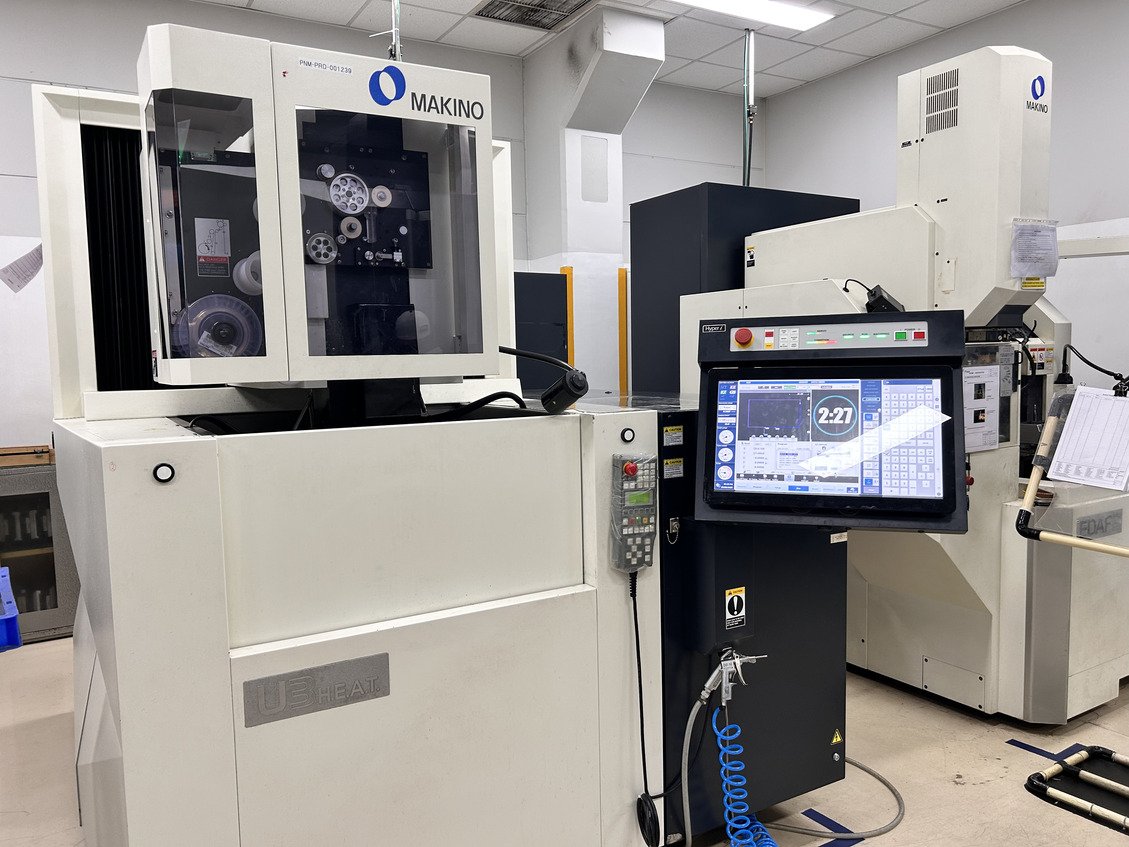

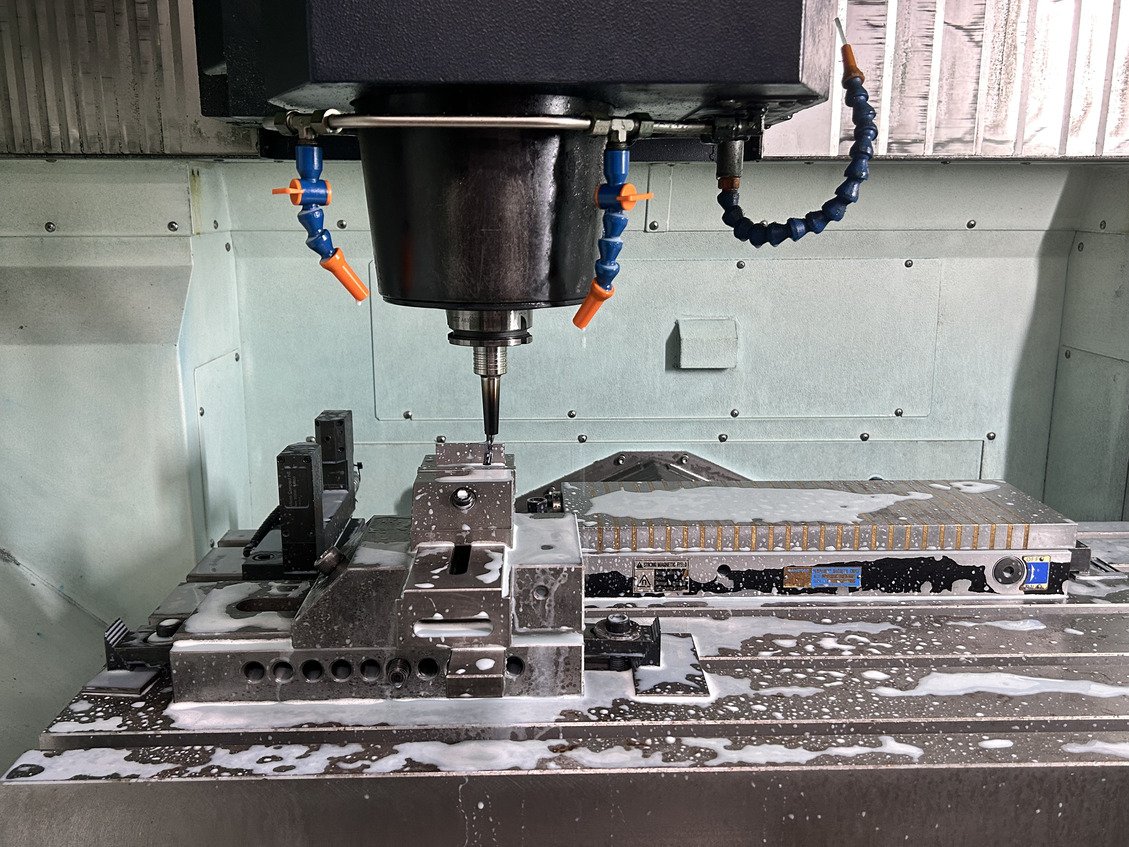

Tool Manufacturing

We specialize in precision mold manufacturing, integrating high-quality cores, cavities, sliders, and slider inserts to ensure smooth and efficient molding operations. Our expertly engineered molds offer:

- Durable Core & Cavity – Delivering exceptional accuracy and longevity

- Precision Sliders – Supporting complex and intricate part geometries

- Custom Slider Inserts – Enhancing flexibility, adaptability, and efficiency

Backed by cutting-edge technology and expert craftsmanship, we deliver high-performance molds tailored precisely to your requirements.

Tool Maintenance

At SPR Takahata, we offer advanced tool maintenance solutions designed to enhance the longevity, efficiency, and precision of moulds and machine components. Leveraging state-of-the-art technology, we ensure thorough cleaning and high-accuracy repairs—minimizing downtime and maximizing your operational productivity.

Mould Cleaning – Ultrasonic & Electrolysis Technology

We utilize an advanced cleaning machine that combines ultrasonic and electrolysis technologies for deep, non-abrasive cleaning. This process efficiently removes carbon buildup, oxidation, and other contaminants—ensuring optimal mould performance and a longer service life.

Mould Inserts & Machine Barrel Screw Special Cleaning – Blasting Technology

Our Uniclean machine employs advanced blasting technology to clean mould inserts and machine barrel screws with exceptional precision. This process effectively removes hardened residues and contaminants while preserving the structural integrity and performance of each component.

Mould Core & Cavity Precision Repair – Laser Welding

We specialize in high-precision mould repairs using advanced laser welding technology. Our process utilizes wire thicknesses ranging from 0.1 mm to 0.4 mm, enabling fine, accurate repairs without compromising the original mould structure. This ensures extended mould life, enhanced durability, and improved production efficiency.