Technology Description

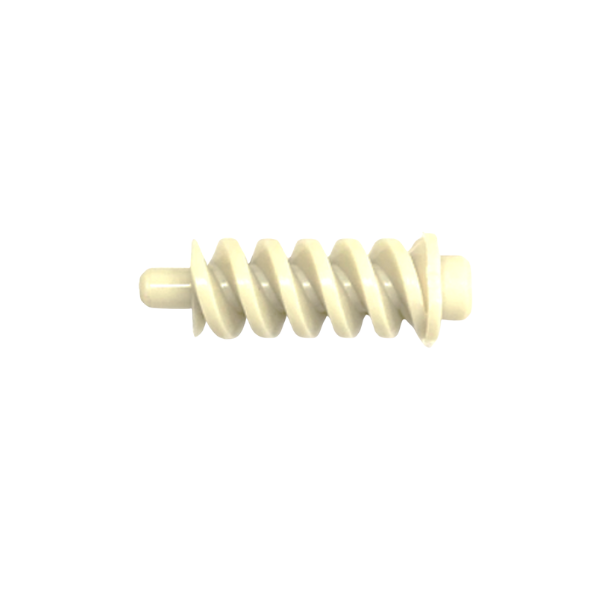

Our High Precision Moulding Technology combines cutting-edge innovations to deliver exceptional accuracy, durability, and efficiency in every moulded component. By leveraging advanced software and automation, we consistently achieve superior results, even in the most complex and intricate designs.

KEY FEATURES

The adoption of high-precision electric moulding machines has transformed the precision moulding industry. These advanced systems offer numerous advantages:

- Enhanced Precision and Repeatability – Exceptional control over injection speed, pressure, and positioning ensures consistent, high-quality parts.

- Energy Efficiency – Significantly lower energy consumption compared to hydraulic systems reduces overall operational costs.

- Faster Cycle Times – Accelerated production speeds lead to higher output and improved manufacturing efficiency.

- Eco-Friendly Manufacturing – Reduced emissions and minimized material waste support more sustainable and environmentally responsible production practices.

Auxiliaries control types

All injection Moulding machine are equipped with required auxiliary equipment as show below

Mould Temperature Controller(MTC) to maintain mould temperature uniformly throughout the mould

Minimizing burn marks through controlled thermal management during moulding

Hot Runner Control System (HRTC) to control and monitor Mould Hot runner heaters

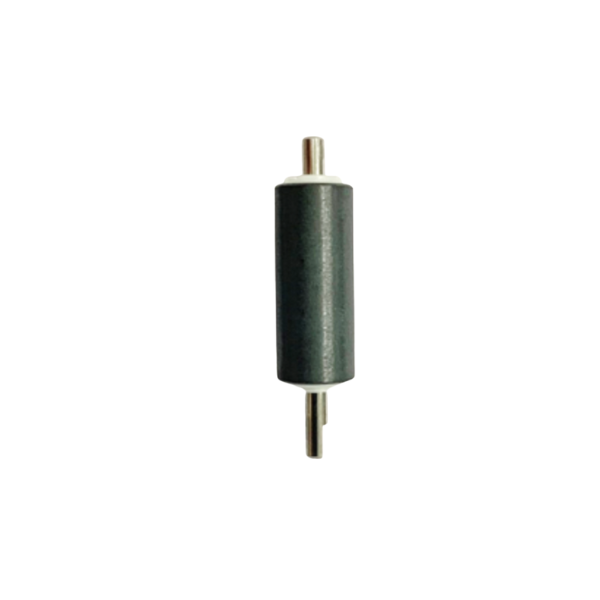

Advanced multi-axis automation for precise and efficient insert moulding operations

Dehumidifier used to remove moisture from plastics before processing

Air Boosters to control air pressure on specific lines

Automated pick-and-place solutions streamline part transfer in horizontal machining operations

Dust Collector Installed Before Plastic Feeding into Injection Moulding Machine

Production line temperature and humidity monitoring systems

Critical process settings are protected through built-in system-level security, ensuring operational integrity

The entire factory, including all production lines, is equipped with air conditioning to maintain optimal temperature and humidity—ensuring consistency in processes, parts, and equipment performance.